Assistant Professor

Jirapat Wanitwattanakosol

Assistant Professor

Napaporn Reeveerakul

Assistant Professor

Pradorn Sureephong

Associate Professor

Ratapol Wudhikarn

Assistant Professor

Pattaraporn Khuwuthyakorn

Assistant Professor

Noppon Choosri

Assistant Professor

Pathathai Na Lumpoon

Assistant Professor

Passakorn Phannachitta

Lecturer

Kittitouch Suteeca

Assistant Professor

Prompong Sugunnasil

Assistant Professor

Pattama Longani

Assistant Professor

Chartchai Doung sa-ard

Lecturer

Phudinun Singkhamfu

Lecturer

Parinya Suwansrikham

Lecturer

Pree Thiengburanathum

Lecturer

Jayakrit Hirisajja

Lecturer

Siraprapa Wattanakul

Lecturer

Jenjira Jaimunk

Lecturer

Apichaka Singjai

Lecturer

Tisinee Surapunt

Lecturer

Porntida Kaewkamol

Lecturer

Pachara Tinamas

Assistant Professor

Krittiya Saksrisathaporn

Lecturer

Thepparit Sinthamrongruk

Lecturer

Waranya Mahanan

Lecturer

Sumalee Sangamuang

Lecturer

Suttinee Sawadsitng

Assistant Professor

Pradorn Sureephong

2022

Danaitun Pongpatcharatrontep

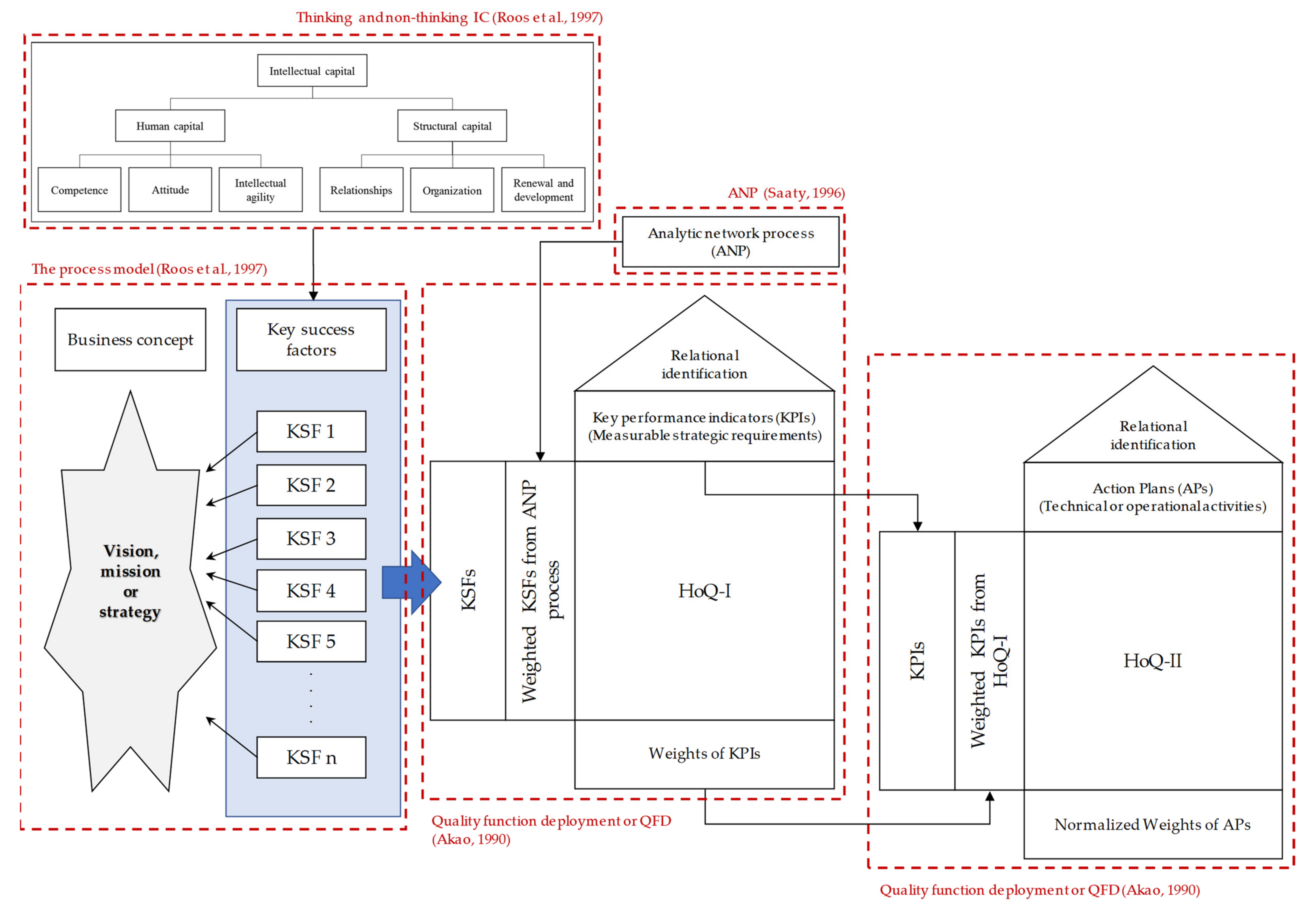

This study develops a new integrated approach for improving deficiencies relating to executives’ intuitive or illogical decisions, mainly found in past intellectual capital management (ICM) methods.

To simultaneously rectify several flaws, the process model of intellectual capital (IC), a traditional ICM method, is integrated using decision science methods—the analytic network process (ANP) and quality function deployment (QFD). The process model of IC is adopted as a core procedure of the proposed ICM approach. ANP is integrated to improve the ability to consider relationships among the IC critical factors and their impacts, while QFD is included to facilitate the systematic consideration and identification of correlations, linkages, and impacts between all IC-related elements from the business concept to strategic plans. The proposed method was applied to two case studies in one real enterprise in Thailand. The results of the implementation reveal the priorities of all IC-related aspects, and the first priority of key success factors (KSFs), key performance indicators (KPIs), and action plans (APs) are all associated with the organization in the structural capital dimension. The results demonstrate that the method may offer advantages with respect to the conceptual expectations and may prioritize critical IC factors and identify their weights. Furthermore, the improved method could indicate the correlations and impacts between related elements, such as critical factors and associated indicators. This study proposes a new comprehensive and systematic management framework by integrating different concepts-decision science methods and the ICM method. To the best of the authors’ knowledge, this improved approach has not been explored or proposed in earlier studies.

https://www.mdpi.com/2227-7390/10/4/626

2022

Somkeit Noamna Noamna

The situation of the covid-19 epidemic is a driving force of the global market's demand increase of electronic devices and parts. Entire electronic component manufacturers, especially the transformer manufacturing industry, which is a device that supplies power to many electronic devices, encounters problems in producing products that are unable to keep up with the quickly increasing demand. This research aims to increase the productivity of small transformers by lean approach. The paper depicts processes relevant to improving production processes, reducing waste, and finding unnecessary processes. The method begins with two actions. First, study the current situation in transformer manufacturing of a case study. Second, study the customer order to delivery process using the Value Stream Mapping (VSM) and analyze entire processes of transformer manufacturing to identify standard time by unit work. The main technique is for measuring working time by timing the forward motion with the time measurement method version 2 (MTM-2). The Cause and Effect diagram was displayed with improving guidelines on two operations. First the concept of lean manufacturing was used in principal role, second the ECRS technique (Eliminate, Combine, Rearrange and Simplify) was applied to reduce "waste"as well as to optimize and reduce the manufacturing process of the transformer. The results lead to an increase in the final product per hour from 45 pieces per hour to 75 pieces per hour which increases up to 30% per hour. In addition, the productivity improvements increased the productivity of 3.46 workers per hour to 6.82 per hour (increase of 97.11%) and production time was reduced from 1,109 seconds to 229 seconds (73.04% of productivity).

https://journals.utm.my/aej/article/view/16712/7897

2020

Passakorn Phannachitta

Context: An analogy-based software effort estimation technique estimates the required effort for a new software project based on the total effort used in completing past similar projects. In practice, offering high accuracy can be difficult for the technique when the new software project is not similar to any completed projects. In this case, the accuracy will rely heavily on a process called effort adaptation, where the level of difference between the new project and its most similar past projects is quantified and transformed to the difference in the effort. In the past, attempts to adapt to the effort used machine learning algorithms; however, no algorithm was able to offer a significantly higher performance. On the contrary, only a simple heuristic such as scaling the effort by consulting the difference in software size was adopted. Objective:More recently, million-dollar prize data-science competitions have fostered the rapid development of more powerful machine learning algorithms, such as the Gradient boosting machine and Deep learning algorithm. Therefore, this study revisits the comparison of software effort adaptors that are based on heuristics and machine learning algorithms. Method:A systematic comparison of software effort estimators, which they all were fully optimized by Bayesian optimization technique, was carried out on 13 standard benchmark datasets. The comparison was supported by robust performance metrics and robust statistical test methods. Conclusion:The results suggest a novel strategy to construct a more accurate analogy-based estimator by adopting a combined effort adaptor. In particular, the analogy-based model that adapts to the effort by integrating the Gradient boosting machine algorithm and a traditional adaptation technique based on productivity adjustment has performed the best in the study. Particularly, this model significantly outperformed various state-of-the-art effort estimation techniques, including a current standard benchmark algorithmic-based technique, analogy-based techniques, and machine learning-based techniques.

https://www.sciencedirect.com/science/article/pii/S0950584920300872